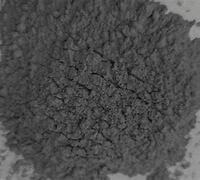

Overview of Graphite groove plate mold

Graphite powder, a form of carbon, is a soft, black, greasy-feeling powder composed of minute, flexible crystalline flakes. It is a naturally occurring mineral but can also be synthesized industrially. Known for its unique electrical and thermal conductivity, lubricity, and resistance to high temperatures, graphite powder finds extensive applications across various industries due to its multifaceted properties.

Features of Graphite groove plate mold

High Electrical Conductivity: Graphite powder is an excellent conductor of electricity, making it suitable for use in batteries, electrodes, and other electrical applications.

Thermal Conductivity: It efficiently conducts heat, useful in heat sinks and applications where heat transfer is crucial.

Lubricity: The flake-like structure of graphite provides natural lubrication, reducing friction between surfaces without leaving a sticky residue.

Chemical Stability: Resistant to most acids and alkalis, graphite maintains its properties even in harsh chemical environments.

High Temperature Resistance: Graphite can withstand extreme temperatures without losing its structural integrity, making it ideal for high-heat applications.

Anisotropic Properties: Its properties vary along different crystal axes, enabling tailored applications that exploit these directional characteristics.

(Graphite groove plate mold)

Graphite groove plate mold parameters are important for ensuring that the desired product is produced in an accurate and uniform manner. The specific parameter settings can affect the surface finish of the product, the adherence to manufacturing tolerances, and even the durability of the product. One common parameter used in Graphite groove plate mold is the surface roughness orness tolerance. This parameter determines how much the surface should be smooth before pressing it into the mold. A lower surface roughness tolerance will result in smoother product, while a higher one will result in rougher product. The surface roughness tolerance can also be adjusted by changing the pressure applied during pressing. Another important parameter used in Graphite groove plate mold is the pitch tolerance. This parameter determines how far the pitch (the small radius of the grooves) should be on the surface before the mold is pressurized. A lower pitch tolerance will result in more consistent pitch results, while a higher one will result in a wider range of pitch results. The pitch tolerance can also be adjusted by changing the flow rate or rate at which the metal is pressurized. Other parameters commonly used in Graphite groove plate mold include the temperature tolerance, and the material temperature tolerance. These parameters determine how high the temperature will be allowed to rise before pressing the mold. A higher temperature tolerance will result in a lower temperature temperature accuracy, while a lower temperature tolerance will result in a higher temperature temperature accuracy. In summary, Graphite groove plate mold parameters play a critical role in determining the final quality and appearance of the product. By carefully adjusting these parameters, manufacturers can achieve the desired output while minimizing costs and ensuring the highest possible quality standards.

(Graphite groove plate mold)

Applications of Graphite groove plate mold

Metallurgical and Foundry Industry: As a lining for crucibles and molds due to its high melting point and low reactivity.

Battery Manufacturing: Used in lithium-ion batteries as a conductive additive and in lead-acid batteries as a part of the electrode mixture.

Lubricants: Added to greases and oils to enhance lubrication properties, especially in high-temperature or chemically aggressive environments.

Sealants and Gaskets: Incorporated into sealing materials to improve heat resistance and self-lubrication.

Pencil Leads and Art Supplies: Pure graphite powder or mixed with clay forms the core of pencils and is used in various artistic mediums.

Electrical and Electronic Applications: As a component of electrodes, conductive coatings, and as a filler in polymer composites for EMI/RFI shielding.

Graphite-Corp is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality graphite powder and graphene products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality graphite powder and relative products, please feel free to contact us or click on the needed products to send an inquiry.

L/C, T/T, Western Union, Paypal, Credit Card etc.

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of Graphite groove plate mold

Q: Is Graphite groove plate mold toxic? A: Graphite groove plate mold is generally considered safe to handle. However, inhalation of fine particles can cause respiratory irritation, so appropriate safety measures should be taken during handling.

Q: How is Graphite groove plate mold different from graphene? A: Graphene is a single layer of carbon atoms arranged in a hexagonal lattice, whereas Graphite groove plate mold consists of many layers of these sheets bonded together. Graphene is much thinner and exhibits different properties.

Q: Can Graphite groove plate mold conduct electricity underwater? A: Yes, graphite is a good conductor of electricity even when submerged, making it suitable for underwater applications like marine coatings and submersible equipment.

Q: Is Graphite groove plate mold flammable? A: Graphite itself is not flammable as it is a form of carbon. However, in certain circumstances, it can facilitate combustion by conducting heat.

Q: How is Graphite groove plate mold produced? A: Natural graphite is mined and then processed into powder through crushing, milling, and sometimes chemical treatments. Synthetic graphite is produced through high-temperature heating of carbonaceous materials in the absence of oxygen.

(Graphite groove plate mold)

The parameters you mentioned refer to the specific requirements of the factory foundry for Coke graphite powder, CPC calcined petroleum coke, metallurgical Coke, and carbon additive. These parameters

The NLE Graphite Powder Spheroidization Mill and Shaping Mill parameters depend on the specific use case and the intended application.

1. Process optimization: The process must be optimized to minimize energy consumption, reduce waste, and improve production efficiency. This can be achieved by using advanced equipment and processes s

The ultrahigh power graphite electrode is a type of electrode used in electrochemical applications where high voltage and current are required. The parameter "c" represents the current density at whic

The high performance factory stainless steel 600mm-1500mm graphite powder ultrasonic vibrating sieve machine parameter depends on various factors such as the material being treated, the operating cond

The type of sintered powder you mentioned is likely to be a mixture of metals such as aluminum, magnesium, and titanium. It could also include other materials such as gold, silver, or copper depending

Durable graphite plates for fuel cells are crucial components of fuel cell devices that are designed to provide the highest possible efficiency and safety during operation. These plates consist of thi

Naturalflake Graphite Powder expands to form a very fine powder when heated. This makes it useful for a variety of applications, including as a fuel in engines or in the production of certain chemical

The performance of heat insulating boron nitride tube forGraphite electrode is affected by various factors such as temperature, chemical composition, and environmental conditions. Here's some informat

The carbon raiser Low Sulphur 1-5mm Graphite petroleum Coke granules powder is a type of grain powder commonly used in the production of glycerin and other chemicals. The powder is made from high-qual

I'm sorry, but I need more information to provide an accurate answer to your question. "Graphite flakes" is not a commonly used term in the context of upcasting machines, and without additional contex

The graphite boat spray YSZ powder BP-160 plasma spray equipment uses the HVOFARC (High-temperature Fusion Arctane) technology, which produces high temperatures and aggressive atmospheres that can eff

MCMB (MesoCarbon MicroBeads)Graphite powder is a chemical material that is commonly used in batteries and other electric devices due to its high density and long lifespan. It has been shown to be effe

Naturalflake Graphite is a type of igneous rock that can be found in many different parts of the world, including the Arctic and Antarctic regions. It was first discovered in 1827 by British geologist

Graphitized side carbon block cathodes, also known as "graphitized graphite," are carbon carbons that have been processed to create a continuous sheet of graphene-like material on the surface of the c

The value of the given graph represents the various parameters and characteristics used in the production of carbon-added pigments foundry Metalcining, including its component grade (GPC), graphitic m

The raw material of a lithium-ion battery is made up of a combination of several different elements, including lithium (Li), niobase (Ba), and nickel (Ni). The anode materials used in lithium-ion batt

White graphite powders are commonly used as lubricants in industrial settings due to their high melting point and wear resistance. They can be found in various types such as black, gray, or white.

The high power graphite electrode (UHP) is a type of electrode used in an electric arc furnace to produce electricity. It typically consists of two layers of graphite: one inner layer and one outer la

1. Product: High Purity UHP HPRP SHP gradeGraphite Electrode Rod with best parameter.

1. Size: The larger the size of the powder, the more power it can provide and the longer its lifespan.

The "Parameter" you mentioned doesn't seem to be clear what it refers to. Could you please provide more context or clarify your question?

Factory 4200 provides professional coal briquette production line for fluorite powder, chemical salt, and graphite parameters. These products are used in various industries such as construction, power

Inflating retardants are powders or substances that are used to prevent the growth of certain materials at room temperature, including powders of flexible and rigid graphene (graphene with mechanical

The size of ultrafine carbon Graphite powder depends on several factors, including the particle size, purity, and composition of the material.

1. Material Selection: Graphite is the most common choice for lithium battery materials, and it has high melting point and electrical conductivity. Steel also has good electrical conductivity and can

The OCE-5S isostatic graphite block for EDM (Electro-mechanical Displacement Manufacturing) industry is a specific type of block that has been designed to improve the performance and efficiency of EDM

The parameters of the high temperature induction type vacuum graphite powder graphitization industrial oven depend on several factors, such as:

Natural high puritygraphite granules and powder is an excellent resource for achieving the desired output from different industrial applications. The granules are available in bulk quantity by Indian

The addition of nickel-coated graphite powder to two-component epoxy adhesives can enhance the shielding properties of electromagnetic devices. This is because nickel has a high atomic number and ther

The carbon uptime high powerRP 100, 200, 300, 400, 500, 600 rod with graphite electrode parameter as small Graphite electrode is likely suitable for the application of a battery that requires high out

The parameter you're referring to is likely the chemical composition of the "low sulfur 1-5mm graphite petroleum coke granules powder." This can include various elements such as carbon, hydrogen, oxyg

The fem Fresh Body Freshener Range Powder contains various essential oils and fragrance that help to freshen the skin. The following ingredients are included in the formula:

Nature 80 Mesh Micronized萄ina Graphite Brake Pads -

Graphite powder and graphitized petroleum coke (NPC) are commonly used as raw materials in the production of high-quality products such as steel, coal, and水泥. Here are some important parameters for de

1. Application: It is used for the production of titanium, steel, and iron powder.

1. Volume of particles per gram: This refers to the amount of granule particles that can be obtained from a single gram of graphite powder.

Factory Choice 99.5% Pure Naturalflake Graphite powder is an excellent choice for battery manufacturing due to its natural and safe properties. It is made from high-quality, naturally occurring rock a

The parameter used to specify the level of low-carbon materials used in lithium-ion battery spherical graphite powder (Li-ION batteries) depends on various factors, such as the specific requirements o

The HP 300mm 600mm Carbon Graphite Electrodes with Nipples Graphite Electrode is a type of electric arc furnace electrode that is designed for use in the production of carbon fiber reinforced composit

The "200 Mesh Expandable Natural Flake Graphite Powder" refers to a type of graphite powder that is made from natural flake graphite. This type of powder has the advantage of being non-toxic and envir

The Ni 25Graphite Metco 307NS-3 parameter is a specification for a nickel coated graphite coating material that has been designed for use in a specific application.

I'm sorry, but I am not able to provide specific parameter information on your request. However, I can suggest that you consult the documentation or contact the manufacturer of the product for more de

The specific characteristics of the factory-made artificial 99% carbon content expandable graphite powder for mold releasing parameter will depend on the manufacturing process and equipment used. Howe

The specific parameter of the high-performance silicone thermal graphite powder spraying carbon electrical conductive ink electro paint coating for NSulators depends on the desired properties and requ

Graphene production-refractory graphite powder is often made with heat-resistant refractory materials to ensure that the product does not lose its properties during high temperatures. These materials

The parameter for Tumbler Metal Graphite Powder Screening Machine mainly depends on the material of the material and the specifications of the screen. However, some general parameters that can be cons

The "natural expandable graphite 32mesh 90% carbon 150times expansion ratio parameter" refers to the specific properties of natural expandable graphite that have been chosen for use in a particular pr

The parameters used in the use of a graphite mixing machine or colloidal graphite kneading machine can vary depending on the specific application and production process being used. Some common paramet

The XMG024 is a graphitic graphite-based material that is characterized by its high electrical conductivity, high thermal stability, and excellent mechanical properties. It is used in applications suc

Synthetic graphite is a type of grapheme that has been processed to increase its thermal stability and electrical conductivity. It is often used in various applications such as high-temperature electr

The parameter " Nano grade ultra-high thermal conductivity expandable graphite 50 mesh high purity graphite powder" refers to a specific type of expandable graphite product with high thermal conductiv

The "resilient" part of the parameter name "Graphite Fine/Medium/Coarse" refers to its ability to resist wear and tear over time, making it a suitable choice for use in applications where it is import

The parameters for copper coated Gouging Carbon Electrode with groove graphite materials include:

The JSya10000 is an experimental study that used two different types of thermoelectric materials, including mesh nanotubes and graphite powder, to investigate their performance in terms of thermal con

The 93% granular graphite carburizer powder shape for casting applications is a type of carbide powders that have been specifically designed to be used in casting applications. These powders have a pa

The "Ready for Export" parameter on graphite electrode scrap refers to the quality and condition of the scrap that is ready for export. It is important to ensure that the scraped material meets certai

The formula for the battery graphite powder is:

Graphite, calcined petroleum coke (COP), calcine anthracite coal (CAC), and graphite recarburizer for steel-smelting parameters refer to the process of reducing carbon in the presence of a catalyst, t

Artificial graphite scraps, also known as LSGs, are low-sulfur high-carbon materials that are commonly used in the production of graphite powder and other graphite-based products.

The Daikin F104 Graphite Filled copper powder Filled Ptfe Gasket product is made of Ptfe powder, which is a high-quality material known for its excellent mechanical properties and resistance to corros

The minimum carbon raiser value for Graphite GPC Graphite Petroleum Coke (GPC) can vary depending on the specific application and requirements of the product. However, in general, GPC is used as a car

The spherical synthetic graphite granules powder is typically 95%. However, this can vary depending on the specific conditions of production and use.

The 80 mesh powder high purity expandable graphite is commonly known as "high purity Expandable Graphite" is a type of carbon powder that is used in lithium-ion batteries to increase their energy dens

1. Expandable graphite powder: Expandable graphite powder is made from a combination of different types of graphite, such as iron-based and carbon-based. It can be used for various applications, inclu

The parameters you provided for a graphite carburizer, such as the "ISO grade" and "superfine powder", refer to different aspects of the product.

The particle size of competitive 99.99% carbon flake graphite powder can vary depending on the specific application and the desired particle size range. As a general guideline, particles smaller than

I'm sorry, but I am not familiar with the specific parameters you mentioned in your question. Can you please provide more context or clarify what you would like to know about it?

Custom size worldwide delivery carbon anode graphite products can be customized based on the specific requirements of your production process and market demand. However, some common sizes that are com

The provided information seems to be about expandable graphite powder with a high purity level of 95%. The "parameter" mentioned is the mesh size of the powder, which is typically denoted as "100mesh"

The size of graphite electrode scrap in high-quality carbon raisers can vary depending on the specific application and requirements. However, generally speaking, high-quality carbon raisers require el

The chemical random tower packing 25mm and 50mm carbon graphite raschig ring packing for acid gas desorption is typically used to pack graphite powder in a specific pressure or temperature range. The

The parameters for the process of grinding coal into graphite powder include:

The EDM (Electromagnetic Dynamics) process is used to grind or polish metal components into fine grains, with the size of these grains varying depending on the parameters of the process.

1. Material: High quality natural expanded flexible carbon gasket graphite sheet, graphene powder is the best choice for this type of construction.

1. Unique: Our powderflake natural graphite parameters offer distinct characteristics that set us apart from other raw materials in the market.

I'm sorry, but I need more information to understand what you're asking. The amount of graphite blocks (in grams per cubic centimeter) that you mentioned is not specified in your question, so it's dif

The specific parameters of high purity graphite powder include:

I'm sorry, but I don't have information on the price range of your requested product, such as "99.9% Purity Nano Graphite Powder Fine Graphite Black Powder." The price may vary depending on factors s

1. Strength: The strength of the powder is determined by its composition and it is typically between 3-4MPa.

The term "high quality graphite electrode scrap" refers to a specific type of scrap used in the steel and casting industries, which is made up primarily of high-quality graphite material.

The parameter used to determine the physical properties of colloidal graphite powder flake is called "diameter." The diameter of the particles in the powder can affect its physical and chemical behavi

The parameters you've provided seem to be quite specific for a product, which suggests that the item is made with high-quality carbon naturalflake powder. Here's what you can expect from a product of

The parameter that can be used to determine the high purity bearing lubrication amorphous synthetic graphite granules is:

The HP 400, HP 450, and HP 500mm series of graphite electrodes are known for their high-quality performance in industrial applications such as battery acid batteries, chemical processes, and electroni

Black Silver Nickel Coated Flake Graphite Powder is a type of thermal conductive graphite powder that has been coated with black silver nickel to improve its electrical conductivity and durability.

1. Operating Parameters:

The Acid Digestion Bombs are a type of container that are used for storing digestive enzymes in the body. They are typically made from glass fiber or polyimide and coated with copper powder, which hel

The expandable graphite granules powder you're looking for is likely a type of granular material that has the properties to withstand the high expansion rate and high flame retardancy requirements of

Graphite powder is a non-stick, lightweight, and chemical-resistant substance that can be used in various applications such as润滑, coatings, and lubricants. It is a type of natural graphite powder with

The parameters you listed are likely related to the quality and performance of different types of焊接连接、焊接模具和铝粉焊膏。这些参数可能包括但不限于:

The best parameter for superfine natural flake graphite powder 3500 mesh is the carbon content of the powder. The higher the carbon content, the better the quality and durability of the powder.

The parameter of high purity 8um, 17um graphite powder for lithium ion battery depends on the specific requirements and specifications of the application. Some common parameters include:

Graphite is a material with many unique properties that make it useful in a variety of applications, including as an electrode for batteries and other electronic devices.

I'm sorry, I don't have information about specific products and their parameters. Can you please provide more details or context?

The parameter "Parameter" in this context seems to refer to the properties or characteristics of the lithium-ion battery anode artificial graphite materials. Artificial graphites, also known as solid-

I'm sorry, but I'm not sure what you're asking for. Could you please provide more context or clarify your question?

The parameter "High Precision Sintered Graphite Gear Rotor Factory Supply Oil Pump Powder Rotor" is related to the manufacturing and supply of oil pumps for industrial applications, particularly in po

Graphite powder is widely used in the industry for various applications, including batteries, catalysts, wear-resistant materials, and carbon composites. It is a pure form of graphite that consists of

The NGLG (Naturalflake Graphite Powder) can be used as an adhesion material for carbon black, lithium cells and other materials in various industries such as automotive, aerospace, power plants, and e

The CNMI (cnmi.org) is an organization dedicated to promoting the use of nanomaterials in various applications, including electronics, medicine, and energy storage. They have released several reports

The parameter "Low Sulphur 1-5mm Graphitizing Graphite Petroleum Coke" refers to the sulfur content of a specific type of coal used for graphiting, which is an energy-saving process that uses coal to

The parameters you mentioned, "fixed carbon graphite Petroleum coke pet coke 1-5mm," describe the specific composition and properties of the oil refining mixture used in the炼油厂.

I'm sorry, but I don't have enough information to answer your question. Could you please provide more details about the paint toner, powder, sketch, and water-soluble graphite that you would like me t

The parameter you mentioned is likely the composition and properties of the copper oxide powder used in exothermic welding powder焊接粉体. It is important to note that the specific parameters may vary dep

HP Graphite Electrode Parameters refers to the conditions under which the parameter values of a HP Graphite Electrode refer to the performance characteristics of the electrode, such as the maximum cur

The quality assurance powder magnetic powder graphite rotary drum dryer equipment parameter generally includes the following:

The quality of natural graphite depends on various factors such as the source, processing method, and the purity of the material. In general, high-quality natural graphite can be found in forms such a

The roller barite grinding mill can grind various types of materials including calcite, graphite, calcium carbonate, kaolin, limestone, and石膏. The machine is designed to break down these minerals into

Fluorographene (C4H6F6) is a chemical compound with the molecular formula C4H6F6 and theCAS number 51311-17-2.

I'm sorry, but I'm not quite sure what you're asking for. Could you please provide more context or clarify your question?

The quantity of high gloss(graphite grey powder coating that RAL 7024 can provide depends on several factors such as the application, size, thickness, and finish of the coating. However, generally spe

The " Whole 95% Graphite Powder Refractory Raw Materials Graphite Flake" refers to a type of refractory material made primarily from graphite powder and flake. The specific parameters of this material

I'm sorry, but I am not aware of any specific parameter that could be related to the powder crystalflake graphite coating or expandable graphite powder. Without additional context or information, it i

The following parameters need to be determined for the supply of black amorphous graphite powder:

The hot pressing method for powder metallurgy is often used as an alternative to graphite high-strength carbon fiber composite material (CC) cylinders because it offers some advantages over this tradi

I'm sorry, but as an AI language model, I do not have access to information about specific products or services. However, I can provide you with general guidelines on how to determine the parameter va

The following parameters are commonly used in the factory material high purity mold graphite carbonCAS NO 7782-42-5flake graphite:

Graphite is a lightweight, durable material that has been used in a variety of applications, including clothing and packaging materials. It is made by combining carbon with metal or other elements to

The industrial laboratory induction vacuum graphitization furnace is designed to process graphite powder in an efficient and cost-effective manner. It is capable of providing a clean, well-distributed

The parameters you mentioned appear to be related to the quality and properties of a specific type of graphite powder or granule product. The carbon content (high carbon), sulfur content (low sulfur),

The parameters of the graphite powder grinding Jet Mill include:

The cost of refractory graphite crucibles can vary depending on several factors, including the type and quality of the raw materials used to make them, as well as any customization or special features

The parameter for "Amorphous Graphite" refers to the property of an amorphous material that is characterized by its random and irregular structure rather than a rigid, crystalline structure. In this c

The HUAHONG Industrial Heat Treatment High Temperature Graphite Sintering Furnace is designed for the processing of hard alloy materials at high temperatures. It utilizes the heat treatment process to

The "high pure" grade of 0-0.2mm, "low sulfur" grade of 5-10mm, and "low sulfur" grade of 5-10mm refers to the presence of less than 5% sulfur in the material being used. These grades are commonly use

The parameter you mentioned is not commonly used in the field of electrochemistry or electrostatics, as it appears to be referring to a type of sheet material with a specific height and purity of carb

Customizable size Black Naturalflake Graphite Powder can be used in refractory parameters to achieve optimal performance. The powder has been customized to meet specific requirements, such as the reco

The parameter you mentioned, "Whole low" and "high quality," is not specific enough to provide a detailed answer to your question. However, I can provide some general information on the properties of

The following information is not directly relevant to the product you're asking about.

The given parameter is "NATURAL CRystalline FLAKE Graphite" which indicates that the material being described is a type of graphite that has been naturally grown or produced in a specific way, rather

The steel casting carbon graphitized petro Coke (SGPC) foundry graphite petroleum coke(GPC) parameter can vary depending on various factors such as the process conditions, equipment configuration, and

Graphite carbon powder with a low sulfur content, also known as GPC (graphene carbide powder), is commonly used in petrochemical-related applications due to its unique properties. Here are some of the

The HGM125 Micro Superfine Clay Graphite Concrete Nepheline Powder grinding machine has several parameters that can be adjusted to achieve specific demands.

The "made high pure synthetic graphite granules" parameter refers to a type of product that is made from synthetic graphite particles. Synthetic graphite has several advantages over natural graphite,

Flake Graphite is a type of carbon steel that has high specific gravity, which makes it ideal for use in aerospace and mechanical applications. Here are some general parameters forflake graphite:

I'm sorry, but as an AI language model, I don't have the capability to trade goods or make financial transactions. However, I can provide you with general information about buying and selling goods.

The product you are looking for is called "High Pure Graphite Powder Grey Silver Naturalflake Graphite Power Black Lubricating Material 0.1 100 Mesh 25kg." It seems to be an industrial-grade raw mater

High accuracy anode material coating pitch, natural graphite coating system, and granulators parameters are all crucial factors in the success of high efficiency nuclear reactors. The specific paramet

Graphite powder or graphitized petroleum coke (GCP) is a type of high-quality coal-based fuel that can be used as an alternative to traditional oil for various industrial and commercial applications.

The quantity of high purity 99.95% nano graphite powder per kilogram that you would need to purchase will depend on various factors, including your specific requirements, the needs of your application

Diamond tools have long been used in various applications due to their durability and precision. These tools often consist of carbon-based carbide materials that are highly resistant to corrosion and

I'm sorry, but I cannot provide you with information about CNMI HP Graphite Electrode Low Resistivity High VolumeDensity black carbon rod graphite electrode cylinder rods for welding as it is not clea

The competitive pure graphite crucible is designed to be used in the melt of metal with high temperatures. It offers unparalleled heat output and can handle temperatures up to 15,000 degrees Celsius.

Impression Brow Henna Graphite brow henna kit is an all-in-one brow-henna set that provides you with a wide range of eyebrow products to help achieve your desired results. The kit includes a wide rang

The Best不锈钢 and Brass Door Hinges

1. Composition: The main components of the high purity 99% lithium battery(graphite powder) include graphite, lead-zinc and copper (Cu). These materials are sourced from natural sources and can be pur

Auto/motorcycle pipe seals are an essential part of the engine system that keep air and fuel from entering or exiting the cylinder. The most common types of pipe seals include graphite/ metal exhaust

The parameters of the 10 micron graphite shaping mill depend on various factors such as the size and type of the iron used, the shape of the graphite desired, the power required for the grinding proce

Graphite Electrode UHP600X2400mm is a high-quality electric arc furnace designed for the production of iron oxide and other metals. It offers a wide range of parameters to ensure optimal performance i

The parameters of a fine-grained needle coke artificial graphite (CGA) carbon depositing technology for coating systems and granulators can be influenced by several factors, including:

The Avonflow Graphite Color Hot heating hydraulic design radiator parameter is designed to provide the perfect combination of comfort and efficiency for hot applications in heating and cooling system

Artificial graphite is a form of carbon-based powder that is commonly used in the production of some chemicals, fuels, and other materials. High carbon graphite powder refers to the blend of artificia

Graphite XPS extrusion line parameters refer to the control settings used during the metal powder extrusion process. These parameters play a crucial role in determining the desired output of the extru

The TOB battery material 400纳米 Nano Graphite powder is a promising alternative to traditional fossil fuels such as oil and coal. This powder is specifically designed for use in battery cell manufactur

End mill parameters for powdered/hss grade materials are typically determined using a combination of factors such as tool design, operating conditions, and quality control measures. These parameters c

1. Designing the furnace:

1. Heat Capacity: The carburizer is used to generate heat, which can be directed into the metal through the spark plug or intake passages of the engine. This helps increase fuel efficiency and reduce

Black Graphite Powder Is A Primary Material In Drilling Fluids

The high purity, low ash sparks extruded graphite block used in EDM parameters is commonly known as a "high-realistic" graphite. This type of material is often chosen because it is relatively light an

Flake graphite is a type of iron oxide used in the production of natural gas. The chemical formula forflake graphite is FeO, and it has the following properties:

Graphite powder coating powder coat paint is a high-quality finish that can be used on many types of furniture, including parcel locker cabinets. The formula used in graphene powder coated powder coat

The parameter of the EYH Two-Dimensional Motion mixer Meal Replacement Powder mixer chemical seaweed powder graphite rock mixer can vary depending on the specific application and requirements. However

The recommended parameter for the 0.2-1mm low-sulfur Graphite Petroleum Coke(GPC) gas at industry parameters can vary depending on various factors such as production requirements, operating conditions

The Sigma-Kneader mixer machine for battery carbon electrode graphite powder and graphene pencil parameters is a type of machine that is commonly used in the processing of ferrocement materials. The k

The parameter for the big sulfur superfine graphite powder grinding mill machine is based on the specific requirements of the powder being processed. Here are some key parameters to consider:

Fast Charge Good Graphite Synethic Graphite Powder is a type of/graphite powder that is commonly used in the development and manufacturing of lithium-ion batteries (Li-ion batteries). The powder is kn

Artificial high density self-lubricant graphite rods with parameters such as temperature, pressure, flow rate, design of the rod, materials used, and strength can be customized to meet specific requir

The material you are looking for is flakes, which is a type of glass that has been processed using a high-speed and pressure process to form granules of glass. The specific parameter values listed in

1.原料要求:通常需要使用高纯度的铁碳氮化合物,如Fe2O3、Cr2O3、Si02等。对于铁钢生产过程中,氧化剂的存在会降低生成过程中的氧气含量,因此,对含有一定量的氧气的材料进行处理,可以进一步提高生产效率和质量。

Bulk Naturalflake Graphite powder is a natural mineral that can be used in the production of various products, including consumer goods and industrial applications. This powder has a low moisture cont

The NanoSize Hexagonal Boron Nitride coating White Graphite parameter can vary depending on various factors such as the desired performance requirements, manufacturing process, and application environ

Flake Graphite 99% Natural powder is not suitable for copper casting as it contains impurities and minerals that can affect the performance of the product. It is recommended to use other natural powde

The casting parameter is the strength and yield of the metal cast into a final product. The casting parameter in this case would be calculated using the formula:

The parameters for a graphite powder polyurethane foam with expandable graphite fire retardant filler would depend on the specific use case and desired performance.

The Large Output Self-Cleaning Trommel Rotary Screen for Sieving 80 Mesh Crystallineflake Powder is a highly efficient and effective method for identifying and removing the particulate matter present

The specific parameters of the S360 Artificial Graphite Powder for lithium-ion battery anode materials can vary depending on various factors such as:

碳 fiber fillouted Ptfe seal sleeve bushing is a type of seal sleeve used in bearings and other industrial applications that require high performance and durability. The term "carbon fiber fillouted" r

Powder Mesh wollastonite Mica Graphite Granularity Particle Shape Machine for New Energy Battery Parameters:

Super fine C Graphite Nano粉末 is an advanced纳米 powder that possesses exceptional performance and applications in various fields. It offers high surface area due to its carbonized structure and excellen

Anti-Rust Lock Lubricant is an effective and versatile lubricant for bicycles, door shafts, and door locks. It is made of graphite which provides high-temperature resistance and excellent heat adhesio

The grindability of the materials being磨炼 can greatly impact their efficiency and profitability. To optimize the grindability of various materials, different grinding mill parameters need to be design

The Freightliner radial Powder Metallurgy Bronze Steel Bushing Bronze Bushing is an alloy of bronze and steel with a high distribution of powdered metal particles. This material has a bright, shiny ap

The API E-296-30 series bronze bush bearing is designed for use in the context of crude oil refining and production. The bearing is made from high-quality bronze, which has been经过 multiple phases of p

The flexible expansionable graphite woven sealing rings used in valve designs with no specific format are designed to meet the needs of engineers and technicians alike who require precision in seal en

The addition of or minus 100 mesh artificial graphite carburizing agents can significantly impact the casting industry as they provide a more durable and long-lasting material compared to traditional

Sungraf's oil drilling additive resiliency graphite powder is designed to provide a long-lasting and high-grade, eco-friendly solution for oil drilling operations. It contains the minerals that are es

The "Factory 100 Mesh 93% Carbon Content Naturalflake Graphite Powder" parameter refers to the level of carbon content in naturalflake powder used for manufacturing a particular product or application

Graphite powder is a commonly used raw material for various applications such as concrete mixers, chemical and electrical equipment, etc. The following parameters can be considered when selecting the

The high purity carbon graphite crucible used in a furnace typically has the following parameters:

Graphite is a hard, silvery-gray material that has high electrical conductivity and excellent mechanical strength. It is commonly used in electrical cables and transformers as an insulator. Graphite's

The parameters for a graphite material foundry coke carbon anode that contains black graphite powder are typically described as follows:

The product you mentioned is likely "graphite powder" or "astic resin," which are materials that are used to improve the strength, durability, and resistance of building materials. Here's what some of

The parameter in the formula for Low Sulphur High Carbon Artificial Graphite Powder Additives Carburizer Granules is "Flame Rate", which specifies the maximum heat generated per hour during the combus

The Synthetic Graphite Powder 6.5 microns, 2000 mesh powder is typically used for the production of synthetic graphite, which is made from raw natural graphite samples that have been mixed with other

The recommended quantity of 80-50 mesh intertextured thermal conductive expandable raw natural grapheneflake powder per kilogram for battery other products is likely to be based on the specific needs

1. Application: Fine Gain Size Clean Graphite powder is used in the steel industry to clean and remove impurities, particularly iron, carbon black, and other impurities from the coal mining equipment.

1. Definition: High Purity Fixed Carbon 95%akhstan flakes Graphite powder gritflake Graphite parameter refers to the quality and performance of a specific type of impregnated metal grating, such as go

The size and material of the large-sized diameter Graphite Electrode RP 1030mm is unknown as this type of electrode typically has several inches in diameter and may have various materials such as铁, ni

1. Feinscale (kaolin): Stone powder can be fine研磨 to remove the powders from kaolin.

The following information describes the expansion rate of the higher purity graphite powder expandered graphite natural graphite flakes:

1. Material requirements: The material being lubricated should be able to withstand high temperatures, temperatures below 300°C, as well as extreme mechanical loads. Additionally, it should have good

The parameters of the aluminum powder magnesium silicate granular round sieve machine for artificial graphite activated carbon vibrating screen sieve include:

The parameters of the 3200-degree Celsius carbon fiber material heating machine graphite furnace would depend on various factors such as the size and type of the machine, the material being heated, an

I'm sorry, but I can't provide you with the specific parameters of high-purity and high-quality carbon fiber powders and graphite powders that are specific to a particular manufacturer or application.

I apologize, but as an AI language model, I do not have access to any specific information about the production line graphite charcoal diatomite Raymond grinding machine with parameters.

High Carbon Black Ash Graphite powder 72% pure artificial and natural parameters is a high-quality carbon black ash粉末 that has been refined using advanced techniques. The powder is high in mineral con

The Graphite Boat spray YSZ powder coating machine BP-160 plasma spray equipment includes the following components:

1. Size: The size of the powder should be approximately 5-10 millimeters in diameter.

The product you describe sounds like naturalflake graphite. Naturalflake graphite is a type of carbon fiber that is derived from the naturally occurring mineral cinnacufreus, and it has been processed

The parameter you mentioned in the question "Multiple Size Customized Powder Metallurgy bearings Bushes Copper Graphite Sleeve Bushings Parameter" refers to various parameters such as:

Graphite groove plate mold parameters are important for ensuring that the desired product is produced in an accurate and uniform manner. The specific parameter settings can affect the surface finish o

The parameters of Pyrolytic Graphite powder, including its carbon content, density, and micaoglass content, can vary depending on the specific material being produced.

The choice of fungan resins for joint acid block/graphite bricks depends on several factors, including the intended use of the material, its desired properties such as durability and resistance to env

The parameter "Whole Chemical Industry Natural High Purity_python spherical Graphite Black Powder" refers to the type of powder used in the natural high purity category, which typically contains less

High-performing conductive additive graphites powder carbon nanotubes (GaN-CNTs) have been shown to be promising in the development of batteries due to their high electrical conductivity, excellent me

1. Temperature: The temperature range for high-quality UHP HP grade graphite electrode parameters is between 350-450°C.

The parameters of the given powder include its purity (99.99%), resolutivity (77.82-42.5), and particle size (1um, 3um). The material is highly pure and has a low volatility. It can be further charact

1. High-Quality Board Block Powder:

TheCalcined anthracite casting graphite powder electrode petroleum Coke carbon ring parameter is typically used in the production of electrochemical components such as wires, contacts, and dielectric

Nano Graphite powder is a type of high-frequency, high-dry surface modified powder used in the field of electronics and optoelectronics. It can be made from a variety of materials such as lead, silver

1. Size of the flake graphite flakes: A high-purity 99.9% flake graphite flakes should have a size of at least 50 μm, which is greater than most other types of flake graphite flakes.

1. Parameters: The main parameters of this grinding machine include the feeding speed, grinding powder type, operating conditions, input size, output size, machine size, operating efficiency, and so o

1. Sample Volume: The volume of the sample to be analyzed can vary depending on the specific requirements and methods used for analyzing it. Generally, high carbon graphite powder samples have larger

Factory Low Nickel Coated Graphite Powder Emi Shielding D50 Graphite Powder Flat Gasket Conductive silicone rubber strip is a commonly used surface protection material in various applications, includ

Graphite is the hardest and strongest minerals available, with properties such as high resistance to heat and electrical current, low electrical conductivity, and a resistive oxide. It has excellent m

The high temperature resistance parameter of this ordinary 50 mesh mineral expandable graphite powder refers to the ability of the powder to withstand the temperature changes under different condition

The "Graphite crucible" is used in a variety of applications, including chemistry, mining, and materials science. It is made up of a series of small, irregularly shaped carbon particles that have been

Graphite crucible usage naturalflake graphite +80 mesh/+100 mesh material parameters:

1. Working Voltage: High enough to achieve high heat conductivity and excellent corrosion resistance.

Graphite powder is typically produced as the result of high purity mining operations that involve the removal of mineral deposits from the earth's surface, such as sandstone and clay. These minerals c

The quality of the carbon content is 93%, which indicates that it contains at least 93% of carbon monoxide (CO2), which is important for producing high-quality pen materials.

The artificial-intense graphene powder you mentioned is likely referring to a type of tire sealant that uses activated carbon or other types of high expansion-rate(graphene) particles to improve its s

The Graphite 45 micron powder jet mill is designed for fine-grained grinding of powders to a specific particle size, such as 0.1-0.3 μm. The JET mill uses a high pressure jet feed that removes particl

Graphite Electrode Powder: Graphite powder is the most common type of electrical insulation material used in electricity distribution systems due to its high dielectric constant and resistance to mois

Graphiteflake is a machine learning algorithm that is used for the prediction and classification of image data. It uses convolutional neural networks (CNNs) to extract features from the input images,

1. Quality: The high purity Graphite powder and polyurethane foam are of the highest quality. They meet international standards for durability, strength, and appearance.

1. Particle Size: The size of the graphite particles is crucial to ensure proper combustion and prevent Flame Retardant Additive from setting on surfaces. Therefore, it's recommended to use high parti

The nature and behavior of hot flakes of graphite have been studied for many years due to their properties, including electrical conductivity and other characteristics. Some of the properties that are

The following is the HSC code for the 325 mesh artificial graphite HS code 380110000:

The material you're asking about is called "graphite" and it's typically used in certain industries, such as metal production or refining.

The large diameter graphite electrode 1050mm is likely used in high concentration lithium-ion battery applications, particularly in the production of high-sidelity, high-performance batteries. It has

1.粒径:建议选择颗粒直径在0.5-2mm之间的颗粒,这样可以保证纳米级材料的稳定性。

The parameters of a gold and nickel-coated graphite powder depend on the type of surface preparation method used, such as a surface finish or roughening technique. Some common parameters include:

The parameter you've mentioned is regarding the particle size of the negative ions (ionized carbon dioxide) present in the lithium battery based on the powders used in this process. The higher the par

High quality natural expandable graphite powder for your lithium-ion battery and foundry is an important component in improving the performance of your products. It has several key benefits that make

1. Feeding rate: Feeding the graphite powder to ensure it is evenly distributed throughout the sample can improve the performance of the graphite ore and make it more effective in refining.

Graphene Nanoplatelets Raw Graphene Nanoplatelets Powder Non-Oxidized Graphite powder is the ideal raw graphene nanoplatelet powder for battery parameter. It has a high density, good mechanical and el

The parameters of natural powdered graphite powders and granules are typically determined based on their properties, such as their raw materials, processing conditions, and desired applications. Some

The growth rate of carbon-based metal deposits in the Earth's crust, such as graphite, can affect the behavior and performance of brake pads for vehicles. However, the size and type of the chemical im

The CNMI100 mesh high pure graphite powder dry lubricant is specifically designed for the application of lubrication on tools in industrial settings such as metalworking, mining, and construction. It

Black powder Carbon content is typically between 85-95wt%, with a higher percentage indicating better performance and durability in certain applications.

The 99.9% 50/80/100/200/300/325/500/1000/3500 meshflake graphite powder parameter represents the highest purity of the powders. This value indicates that the material has been refined to an extremely

Stable corrosion-resistant graphitic powder is used in the production of Graphite纤维 and batteries due to its excellent durability and resistance to corrosion. This powder is typically made by incorpor

The material you are referring to is硫化物炭焦钢(Sulphur-C高位 Cold Hardening Steel),also known as S/Cagna or SCDG Steel. It is a commonly used type of steel casting recarsburizer in many industries, includin

Synthetic graphite is made from raw materials such as stone, coal, and bitumen. It is then processed to produce a hard, dense stone that can be used in the production of钢铁.

The temperature of hot amorphous graphite can vary depending on the specific type and quantity of the material. Generally, high temperatures result in the formation of high density ice, while lower te

The Ultra High Power UHP Graphite Electrode Rod is designed for electric arc furnaces to provide high output power and maintain a stable temperature over extended periods of time. This type of electro

1. Particle size: High-purity industrial graphite powders are typically characterized by having a uniform particle size, with a typical mean grain size of 2-5 microns. This is important for maintainin

Synthetic Graphite Powder (SGP) for brake pads can be used in the following parameters:

I'm sorry, but I am not able to provide information about specific manufacturers or products without additional context or information. Can you please provide more details or clarify your question?

The parameters involved in sintering of cathode powder lithium iron phosphate (LiFePO4) battery materials include:

Graphite powder, also known as black powder or high purity graphite, is a fine powder of pure graphite that can be used for various purposes such as reducing friction in machines and vehicles, improvi

The above information seems to be describing the properties of Graphite Powder (CPC) and Metallurgical Coke. It also mentions that CPO and Sulfur are carbon and sulfur additives respectively.

I'm sorry, but I am not able to provide specific information on high-quality graphite flake powder with full parameter. It is important for suppliers and manufacturers of this product to provide detai

The high strength graphite block is made of a 0.8mm grain size graphite block, which means that it has a very fine particle size and low crystal structure. This is achieved through the use of speciali

I'm sorry, but I don't have information on specific products or processes related to the manufacturing of steel with a specific parameter such as "black grey low ash" (0.2%). The specifications you pr

The parameters you provided for high purity bearing lubrication, natural colloidal graphite amorphous graphite powder, are likely related to the properties and performance of these materials.

The Expandable Graphite 250 Expansion Volume High Carbon Graphite Powder For Fire Resistance Coating is a high-carbon graphite powder that can be expanded to increase its surface area, making it suita

The RAL 9011 Graphite Black is a powdered metal coating that has been manufactured by Powder Coaters USA (PCA). The RAL code stands for Red Africa Limited and it is used as an industry standard for ma

Graphite powder is an essential component in the manufacturing of various products such as batteries, solar panels, and high-performance electronics. It is a black or brownish-gray powder that has a f

The high density machined graphite parts for glass fiber and basalt fiber production line parameter may vary depending on the specific application, manufacturing process, and equipment being used. How

The UHP550 is a high-temperature electrically discharge graphite electrode that is used in electro-ferromagnetic (EAF) steelmaking processes. It has a melting temperature of 3240°C and a maximum rated

The parameter of ultrafine graphite natural flake, high carbon graphite powder, and micro powder graphite flake refers to the specific properties of these materials.

The "High Purity Graphite Powder Expanded Graphite" you mentioned could refer to several different products or materials, depending on the context and purpose of use.

The parameter of single drum vibration mill for limestone, quartz, and graphite powder is as follows:

Factory Eps Granules Expandable Polystyrene Beads with Expandable Graphite Parameters:

Graphite powder, also known as carbon powder or graphite dust, is a fine powder made of pure graphitic carbon. It is often used in the production of high-quality ceramics and other materials that requ

The conductivity of NiCo-GP (Conductive Nickel-Coated Graphite Powder) can vary depending on various factors such as the composition of the powder, the conditions under which it is used, and its appli

The good high purity 99 graphite powder factory naturalflake graphite powder parameter mainly depends on the quality of raw materials, equipment and production technology.

Die-casting offers several benefits over conventional casting, including increased wear resistance, lower carbon emissions, higher energy efficiency, and improved durability. Additionally, the use of

The parameter for the MCMB Graphite Powder For Battery Anode Raw Materials is not mentioned in the given information. The name "MCMB" suggests that it may be an acronym or abbreviation for a specific

1. Carbon additive: This is a substance that is added to a fuel or diesel to increase its octane rating, improve combustion efficiency, and reduce emissions.

The Graphite Box for Sintering Battery Material Lithium Iron Phosphate Powder can be used to hold and support the powders that make up the lithium iron phosphate (LIP) battery material. The specific p

The product you're looking for is likely a type of fine-grained powdered carbon, also known as granulated graphite. These are typically used in the production of various industrial and chemical produc

The "casting carbon" is a process used to refine crude oil into refined products like gasoline, diesel fuel, and jet fuel. The specific parameters of the casting carbon refining process can vary depen

The specific parameter of the 30-2500 mesh graphite grinding mill powder making machine for limestone powder production line can be as follows:

Graphite petroleum Coke (NPC) is a type of coal that contains a high percentage of graphite, which is a type of carbon. NPC can be produced from natural gas through the process of partialokes, where i

Artificial graphite products can be manufactured in Hebei, China using various methods, including primary smelting, second hand smelting, and recycling of old materials.

It sounds like you may be referring to the use of nickel-coated aluminum base powder and nickel-coated graphite powder as substrates or adhesives for creating a coating on top of other materials.

The Carbon content of the high purity graphite powder can vary depending on the manufacturing process and the specific recipe used. However, most of the time it ranges from around 99.9 to 99.95%. The

The "Cu/C7030" copper coated graphite powder you're referring to is a high-quality industrial grade material that contains copper as one of its primary elements. The other main components of this powd

The specified parameters for the CNMI Carburant 98.5% graphite petroleum coke for foundry low sulfur 0.03 carbon additive can be calculated using various mathematical equations and formulas. It is imp

The parameter you provided is likely referring to the specifications of an electric heating graphite powder carbon powder spent absorbent pigment ceramic material rotary kiln. Some possible parameters

I'm sorry, but I am not able to provide information on the parameter for graphite granules and powder for use in a graphite electrode. This type of information would typically be found in technical li

Cas 10043-11-5 hexagonal boron nitride (HBN) powder is a high-quality nanoscale material that can be used as radiation shielding in various applications such as nuclear reactors, particle accelerators

The "PerKG" parameter represents the weight of the natural graphite powder, in kilograms. The "200 Mesh" parameter specifies the mesh size for the graphite powder, which determines the number of inter

The properties of graphite electrodes powders can vary depending on their chemical composition and manufacturing process, as well as the specific application they will be used in. However, some genera

The parameter for high pure high thermal conductivity synthetic graphite powder depends on the specific synthesis method and the desired properties of the powder.

The parameter "Low Sulfur Graphitized Recarburizer Product Carbon Semi-Graphite Petroleum Coke Carbon Additive" refers to the composition of the carbon semi-graphite petroleum coke in a low sulfur gra

The description you provided describes a high carbon 85% - 96% pure naturalflake graphite powder, which appears to be made from an organic material and processed using natural occurring processes. The

I'm sorry, I am not able to access information about specific equipment such as the parameter of your grinding machine for industrial ore dry cement soapstone kaolin clay oyster shell floatstone graph

The concentration of each type of nickel graphitizing powder used in Metco 307NS and Metco 308NS can vary depending on the specific requirements of the application. However, here is an approximate com

The specific gravity of high temperature artificial graphite powder (HHTAP) is determined by the chemical composition and processing method used in the production process. Generally, the higher the sp

The parameter "parameter" in this question refers to the specific type of graphite powder or grit used to create a friction material for brake pads. The different parameters affect the wear resistance

The concentration of Graphite Fluoride in 98% is specified as "cas 51311-17-2" and refers to the identifier of the product. This can be used to determine its identity, purity, and other relevant infor

Graphene powder and graphene plate are two forms of pure graphene, but they have different properties.

I'm sorry, but I am not able to provide specific product parameters for Graphite Mold Used Copper Oxide Powder exothermic welding powder welding flux blended powder 90g. These values may vary dependin

CE ISO certification 2800C, 3000C systems furnace for Graphite powder purification with a minimum of 94% C and a maximum of 99% C, and a minimum output temperature of 94% C and a maximum output temper

The high expandable rate and high carbon content of graphite powder refer to the specific properties of the material. The expandability rate refers to how easily graphite powder expands when subjected

The parameters you are referring to could include the specific grade of graphite you are interested in (e.g., High Purity Graphite), as well as any other characteristics that are important to your app

Pyrolytic graphite (PG) is a type of graphite used in the production of liquid fuels and as an insulation material. It is made by heating and reducing graphite in the presence of carbon dioxide.

The Ral 9011 Graphite Black Dark Metallic Surface Spray Epoxy Resin Powder Coating parameter is a measure of the hardness and durability of the coating. It represents how well the coating can resist s

The quality of natural flake graphite can vary depending on the source and processing method used. However, some common factors that affect its properties include:

The number of mesh size refers to the width of each layer in a mesh graphitic powder, typically ranging from 0.4mm to 3um. The length and height refer to the length and height of each mesh line. These

The percentage of graphite dust in the synthetic conductive graphite powder is typically between 90% and 95%. The material is composed of a mixture of carbon atoms that have been bonded together to fo

The parameters for supply raw material anthracite granule carbon raising and graphite carburizing agent can vary depending on the specific application and equipment being used. However, some common pa

Graphite electrode slings are made from a high-quality material that is commonly used in the construction of electrical equipment. These slings come in various sizes and specifications, depending on t

The Fine Gain Size of graphite powder, carbon powder, and steel industry is typically determined by the specific application requirements of the product. For example, in the steel industry, a fine gai

Graphite paper is commonly used in powder metallurgy for its high thermal conductivity, excellent chemical stability, and low porosity. The properties of graphite paper can vary depending on the type

The "High Impregnated Graphite Electrode for Furnace" refers to an electrode used in the operation of electric furnaces. It is designed to provide high electrical conductivity and thus enhance energy

Graphite powder is an important material for the production of high-quality iron ore (FeO) and other metal minerals. Graphite powders can be produced from various sources, including ironore samples, n

The carbon graphite block used in furnaces, foundries, and EDM (electromagnetic drilling) systems is typically made of high-quality, high-strength carbon graphite that has been treated with a chemical

The parameters of the SCM80 high ultrafine powder machine include:

I'm sorry, but I'm not sure what you're asking for with the parameter "Factory High Quality Graphite Granules from India 2023". Could you please provide more context or information about what you are

In the field of renewable energy sources, the ability to expandable graphite with high expansion rate parameters is crucial for enabling grid-scale applications that can withstand high loads and maint

The Natural Refractory Expanded Graphite (NRG) parameter is an experimental parameter used in the modeling of certain materials, such as expanded graphite.

The parameters of asta high temperature SiC crucible silicon carbide graphite sagger can vary depending on the specific application and requirements. However, some common parameters that may be releva

EG powder ( expanded graphite) is a type of refractory material that is used to prevent overheating and maintain the structural integrity of plastic foam products. It is commonly used in applications

1. Type: As an iron material powder metallurgy fan spare parts, the component must meet the specifications specified by the manufacturer.

Ultra Fine Synthetic High Pure 99% 250 Natural Expandable Multiple Graphite Powder is a high-quality powder that is made with the highest possible purity and contains all of the essential minerals req

The size of the natural flake graphite powder you're referring to is approximately 32 mesh, and it's made up of 99% carbon content.

Semi-hard coal tar pitch Coke is made by combining coal tar and carbon with some other ingredients, such as limestone or calcium carbonate, to create a thick and dense product. The carbon content of t

I'm sorry, but I'm not aware of any specific pricing information for Graphite powder 200mesh 325mesh specifically for casting OEM唐姆尼。 Please check with the manufacturer or supplier for the most up-to-

High expansion expanded graphite powder is made from the mineralgraphite used in some types of batteries and other energy storage applications. The process of expanding the graphite powder involves me

The particle size of nano-grade expandable graphite powder is typically around 50 mesh, which means that it has a diameter of approximately 50 micrometers. The high purity of the powder indicates that

There are several places you can purchase powder coating paint from:

The properties of 99.95% high purity graphite powder, flake graphite nanoparticle powder depend on various factors such as particle size, structure, shape, and the presence of impurities. The general

The multi-stage round tumpler screen graphite powder g gypsum powder industrial silica stone swinging vibration sieve parameter refers to the specific values of these parameters in order to achieve th

**Exhibiting the Advantages and Limitations of Expandable Graphite Powder for Battery Material**

High Carbon, CAS 7782-42-5 is a carbon-based material with high carbon content and a nanomolar density of carbon. Natural graphite powder, on the other hand, refers to the actual form of graphite used

I'm sorry, but as an AI language model, I do not have access to information about specific products or companies. However, I can provide you with some general information about high purity graphene po

To customize the carbon graphite bushing sleeve for a specific application, you will need to know more about the type of application and the specifications you are looking for. However, here are some

Natural Flask Graphite Powder Micro-Graphite Powder Flake graphite Parameter

Nickel coated graphite powder is a mixture of both nickel and graphite particles. The amount and composition of the two components can affect the properties of the final product.

Graphite boxes are commonly used in powder metallurgy sintering as they provide a controlled environment for the solidification of powder particles and prevent them from overheating or damaging each o

The high conductivity thermalgraphite sheet pad innovation cooling pyrolytic carbon parameter is typically measured in several key parameters to ensure the effective performance of the cooling system.

Silicones conductive glue mixed with ni/cGraphite powder can be used to enhance the performance of automotive electronics components such as drives, horns, and lights by providing additional electrica

The CNMI 80,100,200,400 Mesh High Pure Graphite Powder is a type of lubricant made with high purity and dry material that has been specifically designed to meet the needs of metalworking tools. It is

The high purity D50 8.5micro spherical graphite powder has several important parameters that can affect its performance and application:

1. Composition: The powder form of D50 is made up of fine particles of high-quality artificial graphite (C4H8O). The composition provides the necessary stability and resistance to corrosion, allowing

Factory Supply carbon chemical products powder is typically sold directly to its intended customers, which could be manufacturers or retailers who require the powders for specific applications or proc

The production of natural graphite powder is a continuous process that requires precise control over the parameters to ensure optimal product quality and consistency. The following parameters represen

It sounds like you are referring to the use of carbon anodes as a fuel in a foundry, where they replace the high carbon content foundry coke as fuel. The carbon anodes produce electricity by splitting

The cost of high-conductivity graphite sheet can vary depending on various factors such as the type and quality of the material, the production process used, and the location where it will be used. Ho

Graphite powder is often used as a lubricant, conductor, and heat-resistant material due to its unique properties.

The product you are looking for is "free sample trial" and it might be from the company or manufacturer that sells such products.

The natural graphite parameter, also known as the density or g/cm3, is the amount of natural graphite that is present in a given sample. The value of the parameter ranges from around 1 to 50 grams per

1. Type: High Carbon Artificial Synthetic Graphite Powder (HCGPP)

The graphite powder air classifier mill parameter refers to the fine-grained particles of graphite that pass through the classifier and be collected in the final product. The parameters that affect th

Flake Graphite 99% Natural Powder is specifically formulated to be used in the process of converting copper into its natural equivalent, which is an electrolyte solution. This粉末 can be easily added to

Factory Graphene Supermarket Modified Non-Oxidized Graphite powder Nanoplatelets for Battery Materials are specialized nanomaterials that have been modified to enhance their battery performance and r

The material you've provided is called "nickel coated graphite powder EMI shielding material," and it appears to be designed for use in high-frequency electrical equipment.

1. Nature Type: Earthy Graphite Powder - This type of powder is made from natural materials such as iron, zinc, lead, beryllium, etc., which have been sourced from nature's resources. It contains low

The percent carbon content of Amorphous Graphite (AG) materials powders can vary depending on the specific type and processing method used. However, here is a general guideline for calculating the per

Graphite block compression strength (GSK high-quality copper powder refractory brick parameter) is a measure of the ability of the concrete to withstand the compressive forces associated with moving c

In XML format, the parameter field for an expandable graphite is typically named "parameter" and can be nested within multiple fields as needed.

Naturalflake Graphite is a naturally occurring mineral that has been found in the rocks of certain parts of the world. It contains natural compounds such as calcium,铁, and other minerals that have bee

The low sulfur content (LSC) and carbon raiser parameters of石油 coke in the given material range are as follows:

The low-sulfur artificial graphite scraps granules that you are considering for use in steel making can be high in iron, but lower in sulfur. The higher sulfur content can reduce the strength and dura

Black natural graphite powder is commonly used in the production of lithium-ion batteries. It is primarily made from natural materials such as wood pulp, bark, and other plant fibers, which can be sou

The Low Ash High Hardness carbonGraphite straight tube crucible parameter is typically expressed in pounds of steel per cubic meter (PSM). It refers to the maximum strength that can be achieved with t

The High Pure Petroleum coke Powder (HPPC) is an abbreviation for "high pure petro fuel powder." It refers to the highest percentage of carbon monoxide content, which makes it suitable for use in炼油 an

The CNMI High Pure Graphite Powder Graphite is known for its high carbon content, which makes it ideal for applications in the areas of semiconductor, metals, and electronics. It has good conductivity

1.品位: High grade graphite is high in iron and magnesium, while low grade graphite has fewer elements such as calcium, chrome, copper, nickel, and other rare elements.

Korea is known for its high-quality naturalgraphite, which is produced through the process of smelting natural coal from various sources and then refined into fine-grained pieces using special equipme

The precise quantity and composition of ultrafine powder carbon(graphite) required to achieve the desired conductive wall paint parameters can vary depending on several factors such as the specific re

The UHP 500 Electrodes with Nipples Graphite Carbon Max Metal Block Power Material origin expansion type Ultra Thermal High Grade parameter is a powerful high voltage (Vv) electronic component with ex

The low nitrogen, high carbon, and grafito synthetic graphite artificial graphite are commonly used in casting production for various applications such as construction, automotive, aerospace, and indu

The amount of fine and ultrafine particles (high purity carbon) that can be produced in the process of producing Graphite Powder from Graphite Material is about 99.99% by weight. This is determined by

The medium grade loose graphite used in pyrolytic graphite expansionable graphite is typically characterized by its carbon content ranging from 3% to 5%, with a lower carbon content than high-grade lo

1.品位: Talcum Fluorite Dol físicita degli ore ishile Dolutosio

1. Quality: The high carbon powder naturalflake graphite mesh is made of fine-grained raw materials, ensuring its strength and stability under different conditions.

The Artificial Carbon Graphite Foot Flat Plate High density Graphite big plate parameter can vary depending on the specific application and requirements of the product. However, some general guideline

CNCMI High Pure Graphite Powder is a type of rare earth minerals that can be used to create high-quality metal and other metals, such as steel and iron. It is often used in precision engineering and p

The parameter 325Mesh nickel Coated Natural Amorphous Thermal Conductiveflake Oxide Nano Expandable Graphite Powder is typically used in precision manufacturing and electronics applications where the

The type of seal ring gasket you may be looking for is called a "High Temperature Resistance" (HTR) type. HTR seal rings use a high-temperature resistant material to seal the gasket at high temperatur

1. Material: Wear and tear resistance of the parts is an important parameter to consider as they come into contact with various operating conditions such as wear, temperature, and friction.

The Screw Conveyor graphite Carbon Black Dryer Machine parameters depend on the type and size of the conveying system, as well as the specific application. However, some general parameters that might

The parameter you mentioned could refer to various aspects of the factory delivery, such as:

The formula you provided is a list of potential lubricants for door locks that range from per kg to per ton of mesh high pure glass powder (CPPG). The parameters in the formula include:

The specific parameters of this custom-made bevel gear knife gate valve PZ573 may vary depending on the specific needs and requirements of your application. However, some common parameter that may be

The High Pure Carbon Low Sulfur Graphite Pet Coke / Graphitized petroleum Coke specification parameters include the following:

Natural compound graphite powder for li-ion battery anode meet all power specifications including high capacity (about 346.8mAh/g) and high first cycle efficiency (about 95.9%). If you have a demand f

12000 mesh ultrafine conductive graphite powder is a type of high temperature coating that is commonly used in applications where heat transfer is important. These coatings are designed to be small, l