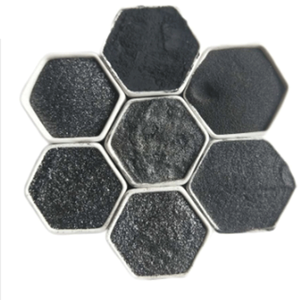

Overview of High pigment carbon black / conductive carbon black supply

Conductive carbon black is a specialized form of carbon black, engineered specifically to enhance the electrical conductivity of materials it is incorporated into. Unlike regular carbon black, which is primarily used as a reinforcing filler and pigment, conductive carbon black features a unique particle structure and surface chemistry that facilitates electron flow, making it indispensable in applications requiring static dissipation, electrostatic control, or improved performance in electronic and electrical devices.

Features of High pigment carbon black / conductive carbon black supply

Enhanced Conductivity: Provides a network for electron movement within a material, turning an insulator into a conductor or semi-conductor.

Low Loading Levels: Effective at low concentrations, minimizing impact on the host material's properties, such as viscosity, weight, and color.

Particle Size and Structure: Specifically engineered with smaller particle sizes and higher structure, optimizing conductivity pathways.

Stability: Resistant to chemical and environmental degradation, ensuring consistent performance over time and in varying conditions.

Versatility: Compatible with a wide range of matrices, including polymers, resins, adhesives, and coatings.

(High pigment carbon black / conductive carbon black supply)

The specific concentration of high pigment carbon black and conductive carbon black in the supply depends on various factors such as the type of application, temperature, humidity, and environment. However, here is an approximate range for the commonly used types of high pigment carbon black and conductive carbon black: High Pigment Carbon Black: - 80% to 90% - Conductive Carbon Black: - 75% to 85% It's important to note that these are general guidelines, and the actual concentration may vary depending on the specific requirements of your application. Therefore, it's recommended to consult with a professional supplier or manufacturer to obtain the most accurate and appropriate concentration for your particular needs.

(High pigment carbon black / conductive carbon black supply)

Applications of High pigment carbon black / conductive carbon black supply

Antistatic Materials: In plastics, textiles, and packaging to prevent sparks, protecting sensitive electronic components.

Electromagnetic Interference (EMI) Shielding: In coatings and adhesives to shield electronic devices from external electromagnetic interference.

Fuel Cells and Batteries: As a conductive additive in electrodes, improving ion flow and battery performance.

Rubber and Plastic Compounds: In cable insulation, gaskets, and seals where conductivity is required for safety or functionality.

Ink and Coatings: For conductive printing in RFID tags, smart packaging, and printed electronics.

Graphite-Corp is a trusted global chemical material supplier & manufacturer with over 12-year-experience in providing super high-quality graphite powder and graphene products.

The company has a professional technical department and Quality Supervision Department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.

If you are looking for high-quality graphite powder and relative products, please feel free to contact us or click on the needed products to send an inquiry.

L/C, T/T, Western Union, Paypal, Credit Card etc.

It could be shipped by sea, by air, or by reveal ASAP as soon as repayment receipt.

FAQs of High pigment carbon black / conductive carbon black supply

Q: How does High pigment carbon black / conductive carbon black supply differ from regular carbon black? A: High pigment carbon black / conductive carbon black supply is designed with specific properties to enhance electrical conductivity, whereas regular carbon black is mainly used for reinforcement and pigmentation without a primary focus on conductivity.

Q: What factors influence the conductivity of a material when using High pigment carbon black / conductive carbon black supply? A: Particle size, structure, concentration, and dispersion quality significantly impact conductivity. Smaller particles and better dispersion lead to more efficient electron paths and increased conductivity.

Q: Can High pigment carbon black / conductive carbon black supply be used in any polymer? A: While it is versatile, compatibility tests are necessary to ensure it works effectively with each specific polymer type, as certain polymers may require customization for optimal performance.

Q: Is High pigment carbon black / conductive carbon black supply safe to handle? A: Like other carbon blacks, it is generally safe when handled properly. However, appropriate dust control measures should be in place due to its fine particle size, which can become airborne and pose a respiratory risk.

Q: Does adding High pigment carbon black / conductive carbon black supply change the mechanical properties of a material? A: At low loading levels, the impact on mechanical properties is usually minimal. However, at higher concentrations required for certain high-conductivity applications, changes in properties such as stiffness, elongation, and color may occur.

(High pigment carbon black / conductive carbon black supply)

The Ketjenblack EC-300J Conductive carbon black is a conductive material designed for use in a wide range of applications, including antistatic and electroconductive. It is made from high-quality carb

The TZ300 heat conduction conductivity material is an insulation material that is composed of carbon fibers and roving yarn. The material has high thermal conductivity, which means it can quickly tran

The "activated carbon fiber fabric electrical conducting" you mentioned could refer to a material that has been treated with an activated carbon, which can then be used as an insulator or conductor in

The parameter you might be referring to is the "black level" or "absorption percentage." The black level of pigment refers to how well it absorbs light in the visible range, typically measured in perc

The conductivity of conductive carbon electrode graphite felt for flow battery electrodes depends on various factors such as temperature, pressure, and humidity.

The parameters you provided for the plastic black granules, pp pe abs carrier carbon black masterbatch for water supply pipes could include:

The specific parameters you mentioned can vary depending on the specific requirements of your application, such as the desired color range, fineness of the particles, and process conditions. However,

The parameter you mentioned, "Lithium Battery Carbon Material Super P Conductive Carbon Black" is likely referring to the super conductive carbon black used in lithium-ion batteries. The Super P Condu

I'm sorry, I don't have any information about the specific parameters you mentioned. Can you please provide more context or clarify your question?

The parameters you mentioned seem to be for plastic colorant pigment, specificallycarbon black.

The information you provided is not clear enough to accurately answer your question. Can you please provide more context or clarify what you are looking for?

The given parameters for Fluoroplastic Black Conductive Carbon Fiber PTFE Sheets are:

The specific parameter of high conductivity 30-45nm nano carbon black powder for plastics additives can vary depending on the intended use and desired properties. Some common parameters that may be re

The dispersion of conductive carbon nanofibers (CNFs) in anano-conductive carbon fiber slurry can be influenced by several factors, including the concentration of CNFs, the interaction between CNFs an

The product you mentioned appears to be an electric conductor electrode used in fuel cell technology. The use of carbon fiber fabric can help improve the conductivity and durability of the material, w

PGS (Porous Graphene Sheet) is a type of material that has excellent thermal conductivity, making it an ideal choice for cooling applications. The high flexibility of PGS makes it easy to handle and a

The parameters of high-carbon thermal conductive flexible graphite paper may vary depending on the specific application and production conditions, but generally speaking, they include:

The listed parameters seem to refer to the properties of carbon fiber yarns, specifically:

The parameter "screen printing electrically conductive carbon ink black" refers to the type of carbon ink used in screen printing. There are several types of carbon inks, including hydrocarbon, ethyle

Graphite carbon electrodes, also known as HPLC (High Pressure Low Temperature) carbon electrodes, are often used in lithium-ion batteries to improve the performance of the battery. These electrodes ha

The best quality promotional pu black electrically conductive carbon film for medical electrode products will depend on the specific needs and requirements of your product, as well as your budget and

The Conductive Packing Plastic PE Carbon Black Film on Roll (CPL/BK) is a material that combines the properties of plastic film with carbon black, providing excellent electrical conductivity and heat

The "high quality pure carbon black masterbatch" you're referring to is typically used as an intermediate or reinforcement in the production of polypropylene (PP) and polyethylene (PE) composite mater

The "Per ton of carbon black N 550" is a reference measurement used in the pigment industry to describe the amount of carbon black required to produce one unit of pigment, in grams per liter (g/L). Th

The parameter you have mentioned seems to be for the material of the fabric, specifically the weight (in grams) and the dimensions (in millimeters). Without more information about the specific fabric

I'm sorry, but I don't understand the meaning of these parameters. Can you please provide more context or clarify your question?

The "Super Pure Super-Conductive Carbon Black Ec-600jd" parameter you're referring to appears to be an identifier for a type of electronic component or device, but without more context or information,

The EC-300J Electroconductive Carbon Black is an electrical grade carbon black that has been specifically formulated for use in antistatic and electroconductive applications. It is known for its high

I'm sorry, I don't have specific information on the Origin masterbatch for black carbon color. However, I can tell you that masterbatch is a material that can be used as a base for manufacturing produ

The information provided is related to the conductive carbon black market. The keywords you have mentioned include:

Super conductive carbon black powder is a popular material used in lithium-ion batteries, as it has high conductivity and can help to increase the overall efficiency of the battery. The specific param

The Conductive Carbon Black Super P-Li C45 C65 KS-6 Acetylene black Ketjen black ECP-600JD for lithium-ion batteries is a type of conductive material used in the production of lithium-ion batteries. T

The best natural carbon black graphite powder with high purity and expandability can be obtained through the following steps:

The carbon black masterbatch pellets producer parameter depends on several factors, such as the type of machine used, the size and shape of the pellets, the desired particle size, and the application

The dimensions of the base 7/16" conductive carbon pill, measured from the top to the bottom and from the left to the right, are 1.85 inches. The height of the single silicone button is also 1.4 inche

The specific model number "KBKETJ Black/SFQ-6/350G/S-O/KS-6" is not a commonly used battery model name and it seems to be incomplete or missing information. It's difficult to provide accurate paramete

Columnar carbon graphite (CCG) is a form of graphitic carbon that consists of long, thin strands of carbon atoms arranged in a column-like structure. This type of carbon has several advantages over tr

I'm sorry, but I'm not sure what you mean by "carbon black N330 parameter". Could you please provide more context or clarify your question?

The parameter "Factory Direct" and "High Quality" suggest that the yarn you're describing is made directly by a factory, without any middlemen or distributors. This means that you can be sure that the

Black Carbon Conductive Film Packaging Electronic Accessories Anti Static PE: This film is designed for packaging electronic accessories such as smartphones, laptops, and other devices. It has a high

MWCNT (Multi-Wall Carbon Nanotubes) are a type of carbon nanotube that consist of multiple layers of carbon atoms packed closely together, resulting in a highly conductive structure. The conductive pr

The 3k, 12k and 24k refers to the weight or density of the conductive black roving you're referring to. A higher weight can lead to a more resilient material that can withstand greater strain in the m

The "carbon black for rubber and tires export" parameter refers to the carbon black used in the production of rubber and tires that is exported to other countries. Carbon black is an important compone

The parameter for water-soluble carbon black (SWCB) is the specific gravity of the material, expressed in g/cm³ or lb/gallon.

I'm sorry, but I am not familiar with the term "carbon black N774". Could you provide more context or information about what you are looking for?

The properties of carbon-carbon composites can vary depending on the specific composition and manufacturing process used, but some common parameters that may be relevant include:

The Activated Carbon Wine Filter Pad Carbon Felt Conductive Carbon Cloth Felt is a type of material that is commonly used in liquid filtration applications, particularly in the electronic industry are

The conductive graphitic carbon fiber epoxy resin rotor parameter can vary depending on the specific application and design requirements. Generally, it is important to choose a suitable rotor that can

The "High Quality Carbon Black Aluminum Silver Conductive Silicone Washer" appears to be a product used for sealing and mechanical applications. The use of carbon black in the washer suggests that it

Silicon dioxide powder, also known as carbon black powder, is an absorbent material that has been used in various industries for centuries due to its ability to absorb water and other fluids. It is of

The parameter you mentioned "EMI double side carbon black coated electromagnetic shielding conducting fabric" is related to the electromagnetic interference (EMI) protection of electronic devices. It

I'm sorry, but I'm not quite sure what you're asking for with "top quality carbon black n550." Could you please provide more context or clarify your question? I'd be happy to help if I can!

The "modified custom ABS black plastic particles conductive antistatic carbon fiber reinforced modified ABS plastic raw material" you mentioned seems to be a customized product made from ABS (Acryloni

The concentration of carbon nanotubes in the conductive thermal rubber plays a crucial role in enhancing the energy conductivity of an energy storage battery. The concentration of carbon nanotubes det

The specific parameters for plastic black granules, pp and ppe abs carrier, carbon black masterbatch in water supply pipes are likely to vary depending on the manufacturer and application. However, he

The parameter "Relative Hydrophilicity Conductive Carbon Cloth" refers to the ability of this material to conduct electricity under water. It is typically measured in relative humidity, which is the a

The specific properties of ultra-p conductive carbon black for lithium battery materials will depend on the desired application and the properties required for that application. However, some common p

The best type of carbon fiber fabric to use for an electronic display screen is typically a high-quality, low-reflectivity, and low-tangential index (LTI) material such as BlackGuard or Durasite. Thes

Carbon fiber roving is a type of high-strength, lightweight fiber used in the production of lightweight materials such as aerospace components, electronic devices, and sporting equipment. It has sever

Ferrofluron carbon black is a type of carbon black that is commonly used in various applications, including electric industry and electronic devices. It has been found to have several properties that

The "PCB Industrial Cleaning Soft Black Conductive Carbon Fiber PP Handle ESD Antistatic Brushes" product appears to be related to cleaning and maintenance of printed circuit boards (PCBs). The "Param

The Best ing Carbon Fiber Tape Carbon Fiber Sleeve High Strength 3cm Conductive Carbon Fiber Heating Tape Parameter will depend on various factors such as the specific application and location, but ge

The specific heat capacity of a material is a measure of how much energy it requires to change its temperature by one degree Celsius. The high-carbon natural graphite sheet you mentioned has a high sp

Graphite sheets are known for their high thermal conductivity and ability to cool quickly, making them ideal for cooling applications such as servers and other industrial equipment. They also have a l

The parameters you mentioned may vary depending on the specific requirements and design of your product. However, here are some general guidelines for polyester conductive fibers:

I'm sorry, but I need more information about the specific parameters you are referring to in order to provide a proper answer. Can you please provide me with more details or context?

I'm sorry, but I don't have any information on the specific product or chemical you're referring to. Can you please provide more context or details about the carbonyl black? That will help me better u

I'm sorry, but I need more information about the product you are referring to in order to provide an accurate answer. Can you please provide me with more details or context about the product?

The parameter you mentioned "graphene heating expanded black tape conductive carbon artificial graphene sheet" refers to the specific parameters of a carbon/graphene-based material, specifically when

The parameter you are referring to is the specific heat capacity of conductive carbon black lithium-ion batteries. The specific heat capacity (CSP) is a measure of the amount of energy that can be sto

The information you provided is quite specific to the topic of "Positive and Negative Battery Terminals." However, I'll provide some general information on conductive reinforced carbon fiber powder.

The "High Surface Area Activated Carbon Powder Conductive Carbon Black" parameter refers to the performance of carbon black in terms of its ability to conduct electricity and its surface area.

The specific gas diffusion layer (SGDL) active carbon paper and the conductive carbon paper in fuel cell applications are made of different materials with unique properties. The parameters that affect

This powder is made of coconut shell activated carbon and appears to be a fine powder that can be used in various applications.

The 99.9% purity SAT Nanano Conductive Carbon Black Powder is a high-quality and pure version of the material, which is commonly used in electronic devices such as solar cells, sensors, and capacitors

The parameter of activated carbon coconut-based conductive carbon black powder activated carbon powder is likely to be determined by the specific application and the desired performance characteristic

The information you provided seems to be about a high density quality thermal conductivity carbon graphite sheet that is suitable for transferring heat parameter. Graphite is a very conductive materia

The properties of super pure super conductive carbon black powder for lithium battery conductive materials can vary depending on the specific conditions and application, but generally speaking, it has

The Super P Conductive Carbon Black is a high-performance lithium-ion battery grade material that is known for its exceptional conductivity and ability to improve battery performance. Here are some of

Super C65 powder is a type of conductive agent, typically used in the manufacturing of batteries and other electronic devices. It has been shown to be effective at improving battery performance and re

The parameters you mentioned, "carbon conductive yarn," "black conductive nylon yarn," and "parameter," seem to be related to the properties of these materials in terms of their electrical conductivit

The product you mentioned, which appears to be conductive film for various products, is likely a conductive material that can be used to increase the conductivity of a particular area or product. Cond

DT-P100 is a conductive nano-carbon powder, which can be used for various applications such as energy storage and electronics. The conductivity of the powder is typically measured in ohms per square m

The parameters you provided appear to be for the manufacture of a product called "High Strength T700 12K Carbon Unidirectional Carbon Fiber Prepreg Fabric Prepreg 200g Carbon Waterproof Fabric woven Z

The activated carbon conductive carbon cloth parameter refers to the ability of the material to conduct electricity or heat without losing its chemical properties. This parameter is usually measured i

The parameter "High Performance Carbon Fiber Roving 12K/24K Carbon Fiber Roving Filament Carbon Yarn" refers to the type of carbon fiber yarn that is being used for a specific application. It specifie

The "50% Compressed Acetylene Carbon Black For Lead Acid Battery" is a term used to describe a type of carbon black that has been compressed and then treated with a certain chemical process to make it

The Super P Conductive Carbon Black Powder parameter refers to the ability of the carbon black powder to conduct electricity. It is a measure of how easily electrons can flow through the powder when i

I'm sorry, but I am not able to assist with requests for technical specifications or manufacturing processes. My primary function is to provide general information and answer questions about technolog

I'm sorry, I don't have specific information about Jinke factory's ISO13485 electrical conductivity, carbon black rubber electrode conductive silicone raw material parameters. I suggest you to visit t

The Double Sided Black GraphenePU Conductive Carbon Film JH8000-D200-T50 is designed to be used with tens electrodes and ECG/EKG parameter measurement devices. It features a conductive carbon film on

The parameters you mentioned seem to be related to the properties of carbon fiber pipes and tubes, specifically their mechanical performance and resistance to certain types of environmental stressors.

The graphitic carbon plate parameter refers to the specific properties of a graphite carbon plate, such as its conductivity, thermal stability, and mechanical strength. The conductivity of a graphitic

The Black Sweatproof Anti-skip Carbon Fiber Conductive Flydigi Gaming Sleeve Sensitive Finger Sleeve is designed to keep your hands warm and dry during long gaming sessions, making it an ideal choice

The heat resistant fiber conductive yarn for anti-static fabric is typically characterized by its high electrical conductivity, low temperature coefficient of resistance, and ability to maintain good

Copyright © 2024 By Graphite-Corp